6 Reasons Why Spreadsheets Don’t Work for Product Information Management

It’s a marketing experience that is all too common, you’re updating or launching new products, and suddenly you’re facing nonstop back-and-forth issues as product details like product size, weight, case count, etc., are worked out and cataloged in the onboarding process. It is all too easy to be faced with missing product information or information that does not align with retailers’ required formats. None of this helps get your valuable products to market.

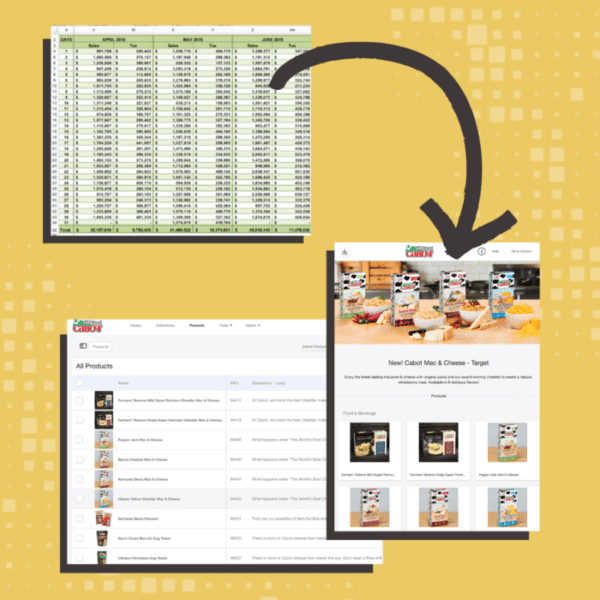

When faced with masses of information to track, sort, and export, businesses often take to spreadsheets in an effort to corral all the details needed to manage product lines. But, when it comes to product information management, spreadsheets are just not cut out for the task. Especially as the consumer demand for new and updated products continuously grows. Since manufacturing companies work with hundreds or thousands of products and need to smoothly onboard regular product updates, managing it all in spreadsheets becomes a full-time job, and every update is slow and error-prone.

This outdated and error-ridden process means products are slow in getting to market, and the risk of bad customer or retailer experiences due to incorrect or inconsistent information out in the market is never-ending. Here’s why spreadsheets don’t work as a product information management system, the risks involved, and how Image Relay’s Marketing Delivery platform can help.

Spreadsheets aren’t your friend… at least when it comes to product information management

Data Entry Errors

Challenge: When working within the restrictions of a spreadsheet, not only are your teams held back by the tedium of manual data entry, but they also face increased chances of product information errors. This is an even more challenging situation for manufacturing marketing teams who struggle to manage thousands of products. You will find yourself facing an ever-unwieldy document with tabs on tabs, resulting in constant scrolling to track down something as simple as an individual product number.

Example: Someone updating spreadsheet cells accidentally enters product information data into the wrong cells, a fairly common and easy-to-make human error. The chance of error only grows exponentially when faced with product variations. For example, you may sell five varying types of drills, differing only by minor details. It is also common for product information to mistakenly be deleted from its cells when moving larger amounts of data around in spreadsheets.

Risk: Manual data entry not only presents a significant bottleneck for business operations, but it also results in an increased risk of product information mishaps and inaccuracies. When the wrong data is loaded and shared during setup, it disrupts business, slows time to market, and can result in a lack of trust with important customers and retailers.

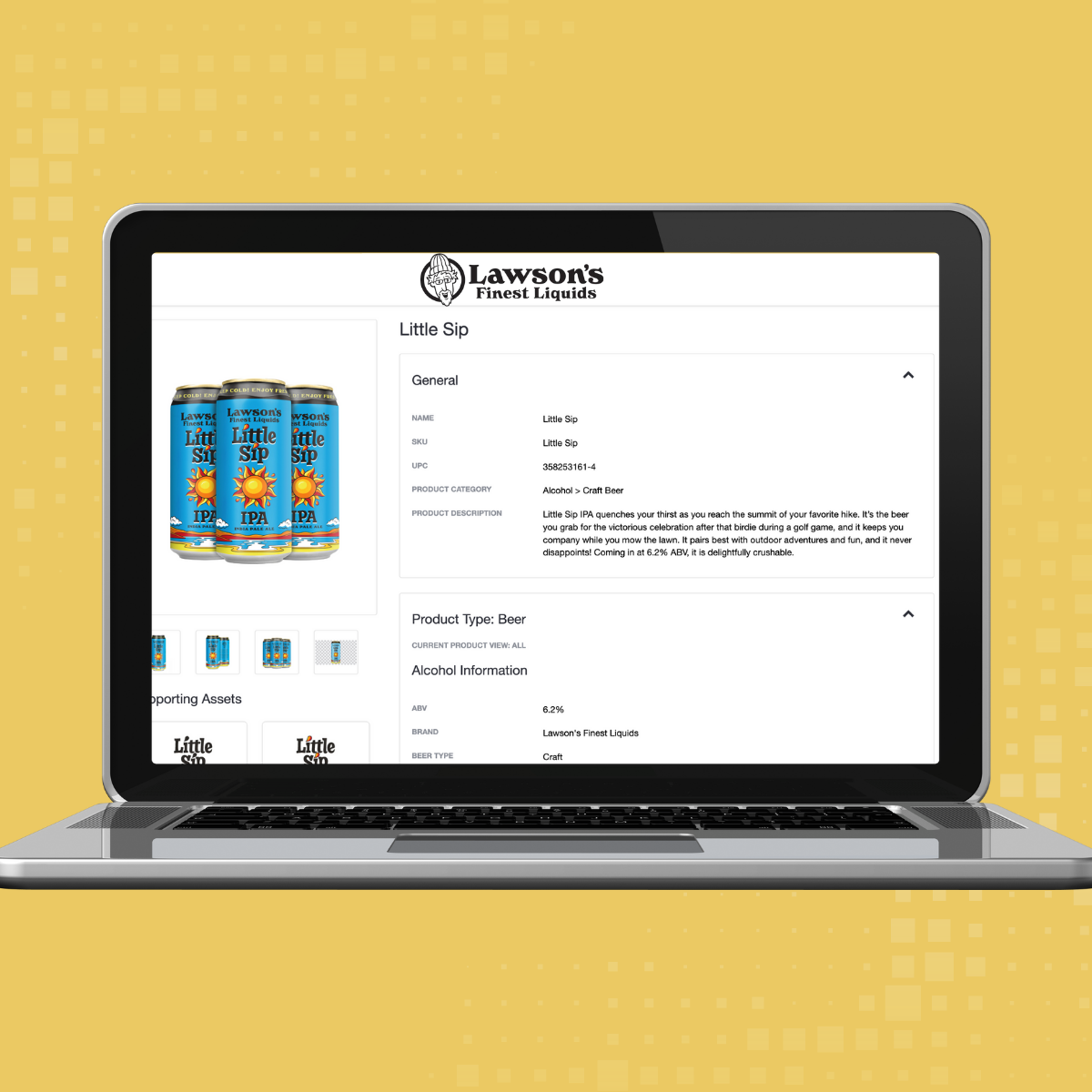

With Marketing Delivery: With Image Relay’s Marketing Delivery platform, any updates or additions to your product information database are synced across your entire platform. Save time and ensure secure, up-to-date, and accurate product information that is ready to be shared with retailers and distributors.

Duplicate Documentation

Challenge: Without Marketing Delivery as a single-source-of truth for all of your product information, whenever a new customer or retailer needs product data, a separate and customized spreadsheet needs to be created and shared. This results in an ever-growing collection of spreadsheets separated amongst a mass of folders. Document duplication slows your time to market, creates dangerous opportunities for inaccuracies, and makes it nearly impossibe to make update product information in a timely manner across your company.

Example: Your team is working to update information for a new product line. However, each retailer has a unique spreadsheet that lists the specific product attributions they require. This means the updates you make need to be then made for every single retailer in each spreadsheet that matches their attributions. Time is tight, the updating process is tedious, and your team is rushing. In the scramble to finish, a few spreadsheets don’t get properly updated and are accidentally shared with your distributor.

Risk: Duplicate documentation presents a high likelihood of errors. With data duplications, your business is exposed to a high risk of that information being shared externally with customers and retailers. These costly errors can result in decreased brand trust, damaged customer relationships, missed sales, and wasted time.

With Marketing Delivery: Image Relay’s Marketing Delivery platform ensures that the process of updating and growing your growing product library is simple, easy, and accurate, with direct channels to your distributors’ attributions. This single source of truth prevents errors, ensures the distribution of accurate data, and accelerates sales.

Employee Continuity and Information Siloing

Challenges: Whenever a team member is out of the office, or there is employee transition or turnover, loss of key information can easily occur. These changes can result in an increased amount of coordination and communication that slows down business operations and increases the risk of product information inaccuracies.

Example: Your team relies on one employee that has been with you since the beginning and serves as the “agency of record” within spreadsheets for all product history and new product information. They’ve been with you forever but suddenly take a new job opportunity and now the rest of the team is scrambling to source essential data in spreadsheets that are saved all over the place or missing entirely. Work slows down significantly as every single data point needs to be sourced and verified.

Risk: This scenario opens your business up to significant risks. It results in lost time to recoup the missing product information and data needed to operate your business, not to mention a slowed time to market. There will often be a chunk of product history that can never be recovered when there is no longer an employee who knows the particular way they stored or retrieved information.

With Marketing Delivery: When you stop working in spreadsheets and transition to a single source of truth platform, it creates product information continuity and protects your brand from lost and inaccurate information. Transition-proof your business with Marketing Delivery to ensure a clear record of your product database allowing employees to easily retrieve information from any point in your company’s history.

Version Control & Product Information History

Challenges: Manufacturing teams are continually expanding product lines. With the launch of these new items, you need a way to safely archive old product information. Spreadsheets are okay for tracking numbers, but they lack any archiving abilities or features to truly protect the history of your product information so that it’s accessible when needed but not sourced by the wrong teams or partners at the wrong time.

Example: A new product is coming out and replacing last year’s model, and you’re working on updating the spreadsheet that contains all of the product data and information for this item. You thought you were finished but accidentally left some of the old model’s information in the spreadsheet. This mistakenly is shared with your customer, who is then frustrated to discover they don’t have what they asked for and need.

Risk: Without a way to clearly archive and save your historical product information, your employees are left open to accessing inaccurate or outdated product information. This can lead to costly product returns and a loss of consumer brand trust and loyalty.

With Marketing Delivery: When your team works with Image Relay’s Marketing Delivery platform, you can control what product version is current and shareable and what is archived. This ensures that what gets distributed is the correct set of product information while your team still has access to historical information at any time. Protect your brand’s product information history and ensure the correct materials are delivered to your customer every time.

Product Information Security

Challenges: When you’re restricted to managing an ever-growing volume of product information within spreadsheets, it opens your business up to significant security risks. Spreadsheets do offer read-only versions of documents, but when this is the primary source for product information management, that is simply not sufficient security for the complex needs of a manufacturing brand.

Example: Manufacturing companies are juggling massive databases of product information without any way for them to moderate or truly control where this information is going, who is seeing it, and what gets edited.

Risk: The risk here is significant. When you’re dealing with pricing or sensitive and key information, if it falls into the wrong hands, it can have serious impacts and lead to a decrease in sales and damaged sales relationships for years to come.

With Marketing Delivery: When working with Image Relay’s Marketing Delivery, sharing product information is easy, fast, and customizable for every team or distributor. Marketing Delivery gives your company the control you need to allow internally approved changes and quick and secure exporting to external teams.

No Product Context

Challenges: Spreadsheets make it impossible to see the complete picture of how essential data points relate or connect to one another. What does another data point or number even matter when it’s one of a sea of thousands? Your team cannot easily make key connections between products or product variations with this separation.

Example: When you’re working with the volume of thousands of products for a manufacturing company, you often need to scroll through miles of cells to get to the next product that you need to compare it against. This makes it almost impossible to find comparisons and key learnings from your product information when working in a spreadsheet.

Risk: When your team misses making key data conclusions or insights, especially within product variations, it can lead to missed opportunities and decreased sales.

With Marketing Delivery: With Image Relay’s Marketing Delivery platform, your company’s product information is visible and accessible in an intuitive way, allowing for key conclusions and optimizations to be easily made.

Ultimately, spreadsheets are useful tools, but they are not built for the varied and complex needs of product information management that manufacturing companies require. They open your business up to high room for error and significant security risks. With Marketing Delivery, your company can finally centralize all of your product information, protecting your brand and accelerating sales.

Marketing Delivery: Deliver Marketing Everywhere

Marketing Delivery offers an essential solution for manufacturing marketing teams by providing a single source of truth that organizes and centralizes ever-growing volumes of product information, helping businesses accelerate their time to market. Marketing Delivery makes sharing your product and brand materials easier, improves your customer experience, and accelerates sales.

Here at Image Relay, we’ve seen and experienced the challenges facing marketing teams and we built this platform as a comprehensive solution to address the lifecycle of how you deliver your brand.